02/06/2025

The DiMAP - Direct Digital Manufacturing Platform Project, carried out within the Integrated Manufacturing Technologies Research and Application Center (SU-IMC) of Sabancı University, located in Teknopark Istanbul, has been launched. Within the scope of the project, which aims to define the future standards of digital manufacturing technologies, SMEs (small and medium enterprises) will be supported in increasing their high value-added product development capacities and opening up to the global market.

The DiMAP - Direct Digital Manufacturing Platform Project, funded under the Competitive Sectors Program of the Ministry of Industry and Technology with the financial cooperation of the European Union and the Republic of Turkey, has been launched. The opening of the project, carried out within the Sabancı University Integrated Manufacturing Technologies Research and Application Center (SU-IMC), was held at Teknopark Istanbul Turgut Özal Event Center with the participation of the Minister of Industry and Technology of the Republic of Turkey, Mehmet Fatih Kacır. At the event, hosted by Sabancı University Founding Chair of the Board of Trustees Güler Sabancı and Sabancı University President Yusuf Leblebici, Ministry of Foreign Affairs EU Presidency Financial Cooperation and Project Implementation Director General Bülent Özcan, and SU-IMC CEO and DiMAP Director Devrim Özaydın also made statements about the project.

Minister of Industry and Technology of the Republic of Turkey Mehmet Fatih Kacır made the following statements in his speech at the opening of the event: “Manufacturing power and technology development capability determine the direction and speed of countries’ development journey. Investments in innovation and R&D studies constitute the key point of sustainable growth and international competitive power. Strengthening Turkey’s brand value in the aviation, automotive, and mobility sectors will be possible by increasing the competitive power of our SMEs in the supply chain of these sectors and by including new SMEs in the ecosystem. It is our priority that our SMEs in these two sectors, which are based on high technology, complete their digital transformation, adopt data-driven and smart manufacturing technologies, and acquire test and analysis infrastructures that will allow them to manufacture at international quality standards.”

“It will be a base that will increase the digital competencies of SMEs”

Mehmet Fatih Kacır, who emphasized that the DİMAP Direct Digital Manufacturing Center will be a base that will increase the digital competencies of SMEs and sub-industry enterprises, said, “Within the scope of the European Union-supported competitive sectors program, we are launching a center that will introduce new manufacturing models to our SMEs in the civil aviation, automotive, and composite sectors. This center will provide our SMEs operating in the civil aviation, automotive, and composite sectors with the opportunity to develop their direct digital manufacturing capabilities and apply manufacturing technologies. It will provide our SMEs, which carry out mass manufacturing in areas requiring high precision, with a critical infrastructure where they can test their products in accordance with national and international quality standards and directly integrate into certification processes. I believe that our center will accelerate the transformation of Turkey's R&D and entrepreneurship ecosystem and the industrial sector.”

“DİMAP is highly valuable for SMEs to achieve an international structure”

Bülent Özcan, Director General of Financial Cooperation and Project Implementation of the Presidency for the European Union, spoke as follows: “We have used approximately 10 billion euros of European Union resources as grants in Turkey between 2002 and 2020. In this context, we have provided financing for European Union projects in many different areas of Turkey, from transportation to the environment, from climate change to regional development. Within this scope, competitiveness and competitive sectors were among the important issues. The DİMAP Project is very valuable for SMEs to achieve an international structure. In this respect, sustainability is one of the most fundamental goals. Sabancı University has almost doubled or tripled the funds it has received in the last 3 years compared to the previous 10 years. It has reached a total fund of 22 million euros. A long journey was experienced for this project to be realized and to reach this stage. First of all, we would like to thank our Minister of Industry and Technology and his team, who provided us with this vision, and I thank Sabancı University very much.”

“We attach great importance to public-industry-academia collaborations”

Sabancı University Founding Chair of the Board of Trustees Güler Sabancı began her speech by stating that Sabancı University attaches great importance to public-industry-academia collaborations, referred to as the triangle of success. Güler Sabancı, who emphasized that DİMAP is a great example of this success triangle, said, “Becoming a world university primarily requires taking part in the right projects with its structure, flexibility, innovation, and research-oriented identity. Sabancı University, as one of the leading research universities of our country and the world in the past 25 years, has been undertaking projects that emphasize its pioneering position with transformative effects on science and society. With DİMAP, it is aimed to put digital and additive manufacturing methods into practice, especially in SMEs. In this way, we aim to popularize data-driven smart manufacturing technologies. I would like to thank our Minister Mehmet Fatih Kacır from the Ministry of Industry and Technology of the Republic of Turkey, who has been one of the biggest stakeholders in the project until today, Bülent Özcan, the General Manager of Financial Cooperation and Project Implementation of the Presidency of the European Union, especially our Vice President Mehmet Yıldız, our Professor Bahattin Koç, our SU-IMC CEO Devrim Özaydın, our project partners, and all the teams involved in the project.”

“We are determined to leave permanent works in the field of engineering”

Sabancı University President Yusuf Leblebici said in his speech, “At Sabancı University, we are determined to leave permanent works, especially in the fields of scientific research and engineering. In this context, the DİMAP platform that we are opening here today is a very important step. In the coming years, DİMAP will serve not only the research groups operating at the university, but also SMEs and Turkey’s industrial manufacturing capacity. The platform is extremely important in terms of both scientific research and industrial management in the future. We would like to express our most sincere gratitude to all our friends who have contributed to this work so far.”

"Our laboratories and DİMAP Project infrastructure are open to all our institutions"

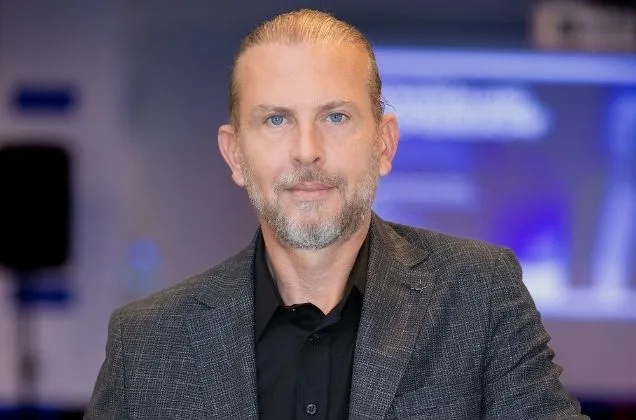

SU-IMC CEO and DiMAP Director Devrim Özaydın said that the main purpose of the DİMAP Project is to bring SMEs together with additive and digital manufacturing technologies, to bring them to the international competitive level and even to exceed this level. Özaydın continued as follows: “With this project, advanced additive manufacturing, material characterization, mechanical testing, and high-tech non-destructive testing infrastructure, especially Cold Spray, which is a new technology in the world, has been brought to our country. Sabancı University SU-IMC Manufacturing and Test Laboratories and DİMAP Project infrastructure located in the Composite Technologies Center of Excellence in Teknopark Istanbul are open to all our institutions. In our project, we will use this infrastructure in the most efficient way by working together with our entrepreneurs, R&D centers, industrial organizations, and universities, especially our SMEs in the aviation, automotive, and composite sectors. We will support the digital transformation journey of our companies and increase their capacity to manufacture functional parts by utilizing advanced manufacturing techniques such as additive manufacturing. We will especially ensure that our SMEs can carry high value-added prototypes to the operational environment. We will continue to manufacture value-added outputs for our country. We would like to thank our Ministry of Industry and Technology of the Republic of Turkey and our Minister of Industry and Technology Mr. Mehmet Fatih Kacır, the Presidency of the European Union Financial Cooperation and I would like to thank Project Implementation General Manager Bülent Özcan, our Vice President Mehmet Yıldız, our Professor Bahattin Koç, our partners, and all the teams who contribute to the project.”

The Project aims to increase the manufacturing capacity of industrial companies

DiMAP, with a total budget of 9.8 million euros, aims to develop additive manufacturing processes supported by data-based smart manufacturing systems and integrate these processes with testing, characterization, and quality control elements. The platform aims to support the digital transformation journey of industrial companies, especially SMEs operating in the civil aviation, automotive, and composite sectors, to increase their capacity to manufacture functional parts by utilizing advanced manufacturing techniques such as additive manufacturing and to enable them to carry high value-added prototypes to the operational environment. In line with this goal, the project directly touches the regional industrial ecosystems in the leading cities of Turkey in industrialization, Istanbul, Bursa, and Kocaeli. The project covers not only the technical infrastructure and product development processes, but also the support of the basic needs of companies such as certification, human resource development, and access to financing.

A strong partner network

The DiMAP Project, which aims to define the future standards of digital manufacturing technologies, is positioned as a holistic platform that increases the product development capabilities of companies, supports their access to the global market, and supports them in their transformation journeys, with the guidance of Sabancı University’s research vision, SU-IMC’s technical power, and partner network. The project is carried out with a strong partner network consisting of organizations such as Bursa Industrialists and Business People Association (BUSİAD), Kocaeli Chamber of Industry (KOSANO), Eastern Marmara Development Agency (MARKA), Istanbul Development Agency (İSTKA), SAHA Istanbul, and Teknopark Istanbul, within the scope of Sabancı University’s efforts to strengthen university-industry collaboration. Partner organizations act as a bridge between SMEs in their regions and sectors and DiMAP.